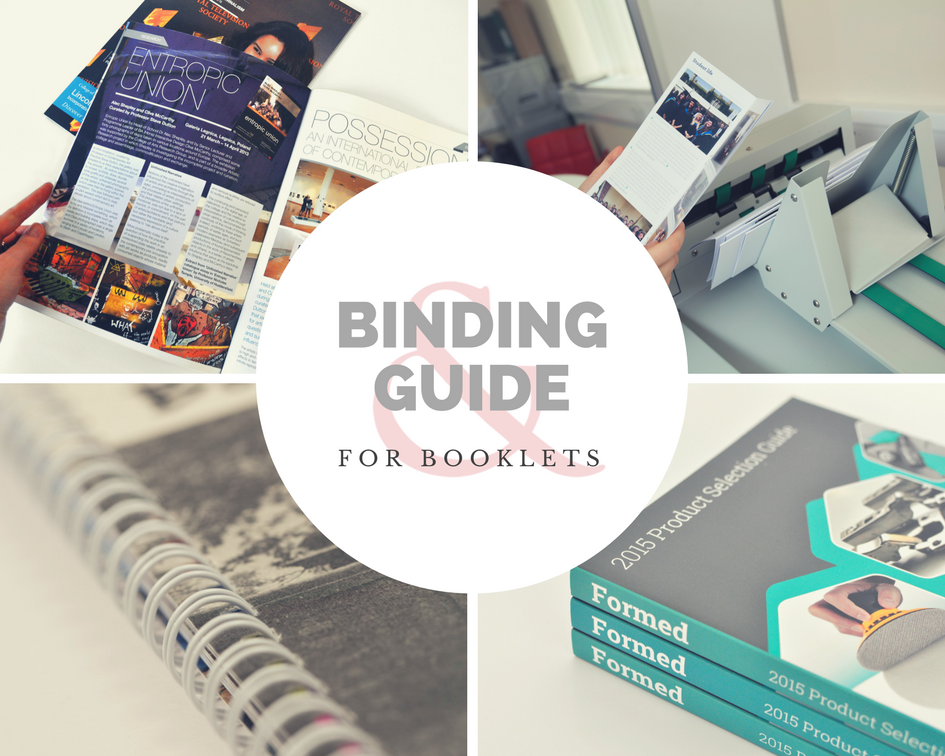

Binding guide for booklets

Considering the binding of your next booklet or brochure print is just as an important decision as the paper it will be printed on. The binding you choose will finish the booklet and turn it into a professionally printed document. There are specific reasons when and why you should use each binding option, and understanding them will help you when working on your next project.

To help you understand the possibilities available, we have put together this ‘binding guide for booklets’ to help you select the best choice for your project.

Saddle Stitch (stapled)

This simple binding style offers quality at an efficient rate. The technique involves punching a wire through the gathered pages at the centre spine. The pages are then folded in half at the spine to create a booklet.

In short:

Pages are printed, gathered, stapled and folded to create a booklet

Why choose this option?

Cost effective

Creates a professional document quickly

Durable and flexible

Can be printed in a variety of sizes

Perfect option for:

Magazines and newsletters

Handbooks

Prospectus

8 – 56 pages

Perfect Bound

The sections of the booklet are folded and then roughed up at the spine to help them bond with the glue. The pages are then gathered up and glued to the cover page. This method is more expensive so works out more economically on larger print runs.

In short:

Pages are held together to the cover by using a strong adhesive

Why choose this option?

Provides a high standard finish

More cost effecting than hardback binding

Covers can be a thicker weight to the inner pages

16-180 pages

Perfect option for:

Children’s books

Executive brochures

Novels

Wire Bound

Leaves of paper are punched to allow a wire to pass through the holes twice. Pages lay next to each other flat, so is a perfect option for documents that need to be written on. Wires are available in a variety of colours, and special covers can be added for a stronger finish and added protection.

In short:

Pages are punched and a wire is passed through the holes to hold the booklet together.

Why choose this option?

Can be used for a variety of booklet sizes

Wire is durable, perfect for documents that are used frequently

The document can be opened out and lays flat on a surface

4-275 leaves

Perfect option for:

School diaries

Training manuals

Record books

Square back

Using square back stitching to finish booklets transforms the book into one that appears to be perfect bound, but at a lower cost. The document will have the added value of strength because of the stitches, but still the look of a perfect bound booklet. This option is cost effective and can be used on short print runs of around 500. We would always recommend having the covers of your perfect bound booklet laminated, as this prevents the edges from cracking.

In short:

Booklets are stitched then creased to give the professional look of a perfect bound document

Why choose this option?

Cost effective, professional looking option for short print runs

Added strength and durability for the staples

8-56 pages

Perfect option for:

Programmes

Magazines

Portfolios